PDE protocol converter

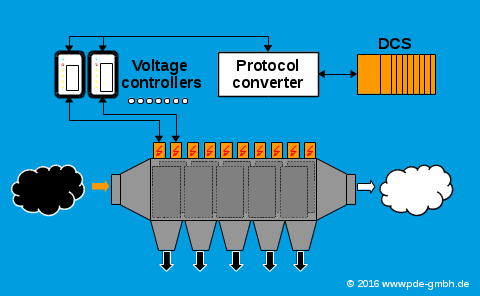

PDE GmbH has developed a protocol converter which enables modern digital control systems to communicate with Lurgi COROMATIC R voltage controllers for electrostatic precipitators. The project was conducted with Siemens Australia and four converters will be deployed in the Stanwell Power Station.

What is an electrostatic precipitator?

A device which separates particles from a gas stream by passing the carrier gas between pairs of electrodes across which a unidirectional, high-voltage potential is placed. The particles are charged before passing through the field and migrate to an oppositely charged electrode. These devices are very efficient collectors of small particles, and their use in removing particles from power plant plumes and in other industrial applications is widespread.

The electrostatic precipitators are a key component in the exhaust gas aftertreatment systems of modern coal-fired power plants. Without them, the exhaust gas would contain high amounts of particles, making it hazardous to breath.

The key to successful operation of electrostatic precipitators are the voltage controllers. From the mid-eighties till the late nineties, the Frankfurt-based engineering company Lurgi AG has manufactured the COROMATIC C, COROMATIC R and COROMATIC F voltage controllers, which are still in operation in many coal-fired power plants all over the world.

What does the protocol converter do?

Whenever such a coal-fired power-plant is modernized, it usually turns out that the COROMATIC controllers are still performing well. The hardware is extremely robust and if spare parts are still at hand, why replace the COROMATICs?

If a modern digital control system (DCS) is installed, there is usually no way to directly retrieve data or send commands to COROMATIC controllers. This is not necessarily an obstacle: The COROMATIC controllers can operate in stand-alone mode and may have operated in this mode for quite a while. Nevertheless integration into a DCS offers many benefits.

This is where the protocol converter comes in: It translates the COROMATIC protocol to MODBUS and vice versa. This enables almost any modern DCS to communicate with the COROMATICS. Since the DCS has an overview over the whole process, the COROMATIC controllers can be operated more efficiently than in stand-alone operation.

If you are operating Lurgi COROMATIC controllers and wonder if you could operate them more efficiently, contact us.